And now for another installment of “I should really get around to posting this one of these days”. This summer’s anodizing class was cancelled (along with the pewter casting class) due to low enrollment. Fortunately, the open sessions went ahead, so I managed to get my anodizing fix after all. I wanted to try a […]

And now for another installment of “I should really get around to posting this one of these days”. This summer’s anodizing class was cancelled (along with the pewter casting class) due to low enrollment. Fortunately, the open sessions went ahead, so I managed to get my anodizing fix after all. I wanted to try a few new masking techniques this time around, so I stuck to using the 3 same colors for simplicity.

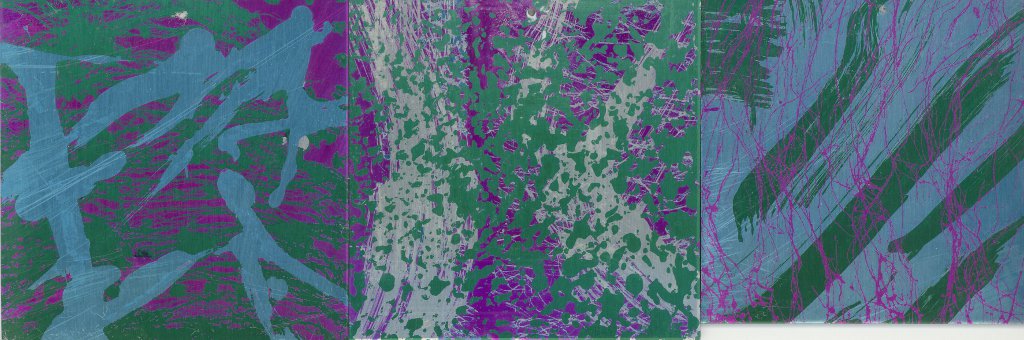

For the left two samples, I masked the blue with UHU Por (sold in the US as UHU Creativ), which is similar to rubber cement but comes in a tube. It masks just like rubber cement, but since you squeeze it from an applicator tip rather than brushing it on, you can make finer lines (of course, you could do the same with rubber cement in a blunt syringe). On the top left sample, I masked the green by spraying some 3M 77 aerosol adhesive through a perforated aluminum plate for the polka dot effect.

The green in the center two samples was masked by sponging on the absolute cheapest white spray paint carried at Wal-Mart. However, the ‘sponge’ used was actually the filter from a wet/dry vac – the very large open celled structure of the filter makes for a pattern that masks with harder edges due to how heavy a paint load the filter will pick up.

The purple in the right two samples was masked with Krylon webbing spray paint (silver in this case, but the color doesn’t matter since it’s used for masking and then removed). This worked quite well, and I’m wondering if the nozzle from the can can be used to spray a webbing pattern with other (cheaper) spray paints. However, I recall reading somewhere that the webbing effect as practiced by custom car painters requires a thicker paint blend, so perhaps the same holds for aerosol cans.

These samples show more of the same, along with swipes of rubber cement on a brush (which is still a favorite technique for throwing down ragged bursts of color).

After playing with samples, I dove into actually anodizing a paintball gun that I had polished and prepped. Frankie took some excellent photos of the process and posted them on his blog. I was very pleased with the result, though I messed it up a little during the sealing on some of the parts. I had the above samples in the same boiling water bath, and the green on the samples leached out and colored the blue on the gun parts into a slightly aqua color. Additionally, there’s a spot on the trigger frame where the anodizing can be scratched off with a fingernail, so something isn’t quite right there (of course, this is the first time I’ve tried anodizing parts that are actually intended to be used). I wound up purchasing some proper anodizing sealant solution, an immersion heater and an insulated cooler to hopefully improve the sealing stage. Now I just need some free time to go visit Frankie and try it out with another gun.

What’s mean of the anodizing class ?