Filament is the primary consumable on Stratasys machines, but not the only one – the build trays are also considered consumable. On newer machines that use plastic trays, the official recommendation is to use them for only a single print, but that starts getting expensive fast, so users will wipe them down with acetone or […]

Filament is the primary consumable on Stratasys machines, but not the only one – the build trays are also considered consumable. On newer machines that use plastic trays, the official recommendation is to use them for only a single print, but that starts getting expensive fast, so users will wipe them down with acetone or try sandblasting them to freshen up the surface for more use. The old FDM series machines that I have don’t use plastic trays as a build base, but rather a foam square. I had already investigated alternate materials with poor results, and John Branlund had started to look into craft store foam instead, as it seemed to be the material to beat. We eventually concluded that the foam is most likely General Plastics FR-7104 modeling foam based on the sample kits that the company provides. I haven’t pursued this further, however, as I can’t imagine that shipping on a 4’x8′ sheet of rigid foam could be anything close to ‘low cost’, and I have about half a dozen extra foam bases anyhow. However, I’ll be turning the FDM 1600 loose to be used by other Makerspace members very soon, and I’d like to give them the ability to simply replace the foam bases as they deem necessary without burning through what I have left.

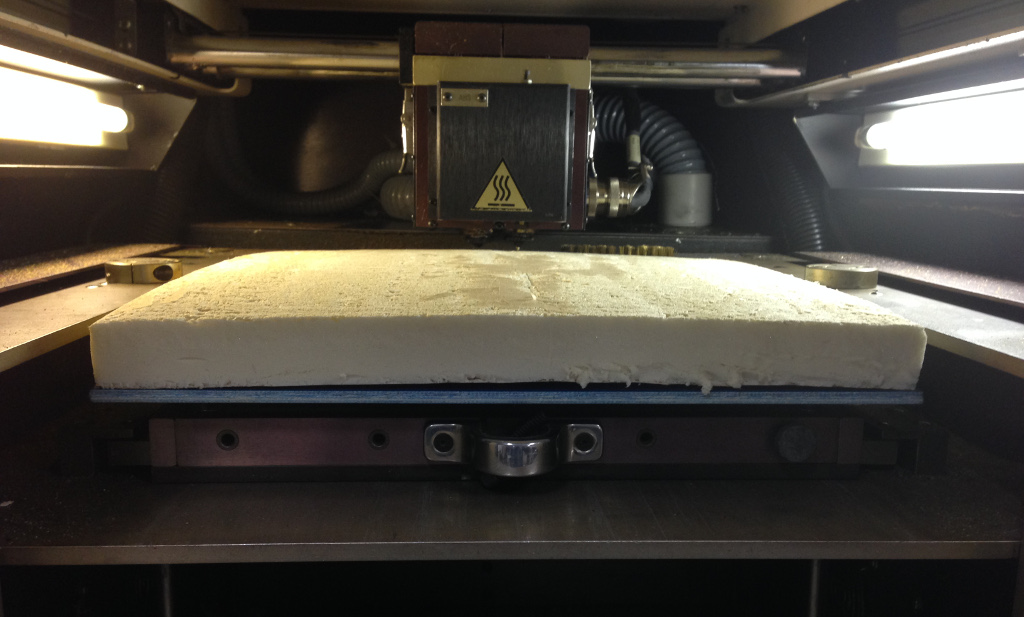

Some time back, fellow Makerspace member the_digital_dentist was experimenting with various slurries and sprays to improve part adhesion on his very large scratchbuilt 3D printer. I gave him a Stratasys foam base to try, and it worked like a champ (almost too well, since the ABS support doesn’t break away nearly as easily as HIPS support). I mentioned my woes in trying to source more of the foam, and he suggested trying the foil-sided polyisocyanurate (PIR) foam that you can find at some home improvement stores, and gave me a few pieces to try. I cut a 12″ square, peeled the foil from one side, and sprayed the other side with 3M 77 adhesive before pressing it onto my material testing plate. I put the tray into the machine and let it heat up before testing it.

Unfortunately, I failed to take differential thermal expansion into consideration. With the chamber heated to 70 C, the foam expanded ever so slightly, buckling upwards due to the foil still being attached on the underside.

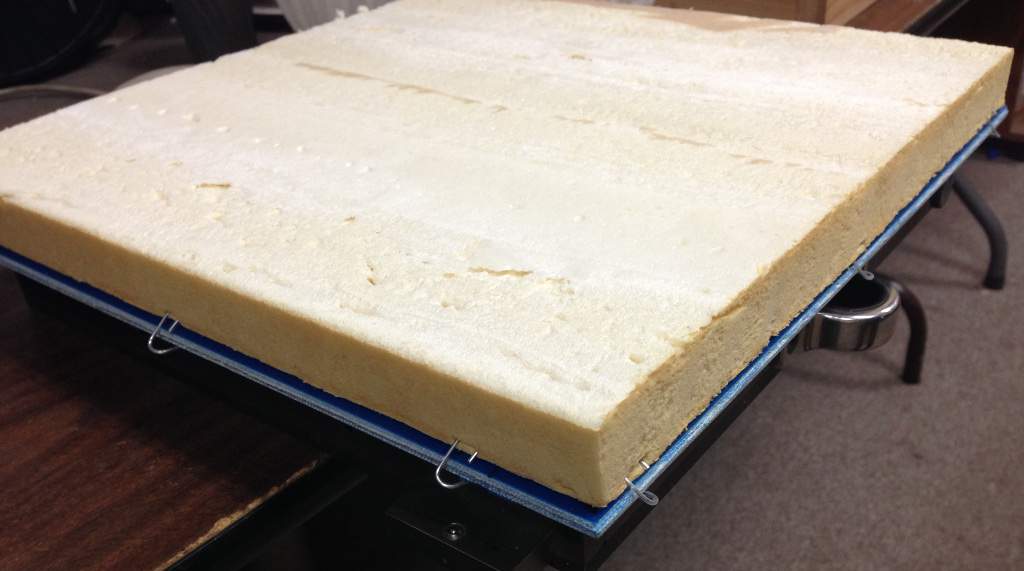

I removed the foil from the underside, and lacking anything better, used a bunch of paperclips around the perimeter to secure the foam.

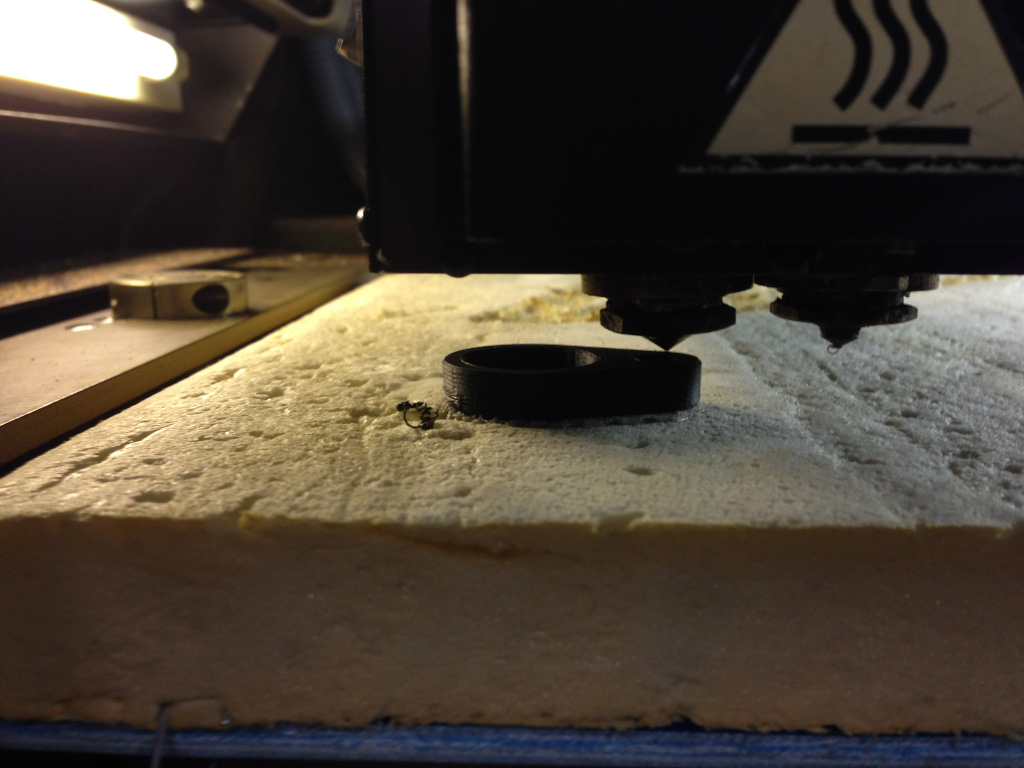

While the PIR foam surface isn’t as smooth as the Stratasys bases, it’s ‘good enough’ for my needs and a test print went fine.

The part and support removed from the PIR foam very easily with just a little tearing of the substrate. Overall, it’s still not quite as good as the FR-7104 foam (tears more easily and doesn’t grip as well), but for a cheap, readily available material, it’s the best thing I’ve found so far. The only drawback is that locally available sheets are only 1″ thick and I need 1.25″ of thickness, but shimming up the base from the bottom shouldn’t be much of an issue.

Hello Haveblue,

I coudnt find your Email adresse so Im writing in your comment section.

I did get a FDM 3000 modell but cant get it too run. Hopefully you can help me out.

1. After getting some NV Memory errors i did try to load the paramter file i got with the mashine but after that it doesnt even go to home anymore. Do you have a paramter file for me?

2. The second problem is that i cant get the Extduer to work. When i push the load button the motors and gears dont move as if there is no power. But the Head gets warm and both of the hotends heat up. I cant get the filament to move into the head.

I would really appreciate your help. Thank you very much in advance for everything.

Hi HaveBlue,

I also have an FDM 1600. I’ve built many parts on it, however, it has stopped all head movement. Would you be able to help or advise me?

Would you respond to my email address?

Thank you,

Ed

I guess I will hop on board the help train! I am looking at purchasing a Stratasys 1600 like yours but the owner says it shows the error “torque limit exceeded” on the machine when it tries to run. Is this something that is easily fixable or could I be in for a long haul? I would hate to pay money for a giant paper weight. 😀

Sorry to bother you with this, but you are the only person I can find talking about them!

Thanks!

Dane

If you see ‘torque limit exceeded’, it could be as simple as jammed filament or a clogged head – the way to test it would be to remove the motor blocks from the head and see if the error is still tripped. If the error comes up even when the drives aren’t actually feeding filament, it could be a wiring short in the ribbon cable coming from the motors.