One thing I’ve noticed about EZ-LAM 60 epoxy is that the maker wasn’t lying about not using it when the ambient temperature is under 65 °F. It’s now been over 48 hours since I laid up the two pod molds, and the fiberglass/epoxy is still slightly pliable. I’m sure in another week or so when […]

One thing I’ve noticed about EZ-LAM 60 epoxy is that the maker wasn’t lying about not using it when the ambient temperature is under 65 °F. It’s now been over 48 hours since I laid up the two pod molds, and the fiberglass/epoxy is still slightly pliable. I’m sure in another week or so when standard late spring temperatures finally arrive the epoxy will fully cure in 24 hours when in my basement, but for the colder parts of the year I’ll need to use EZ-LAM 30 or just start experimenting with the West System hardeners. As such, this is a quickie post on removing the weights from the Diamond 2500 powered sailplane.

I hate seeing RC planes come from the factory with a bunch of steel washers glued into the nose – if the plane has the center of gravity too far back, I’d rather add more fuel to the front (in the form of a bigger battery) than dead weight. I think I know why manufacturers do this, however – they want to be absolutely certain that the plane is stable, even if it means reduced performance. “A nose heavy plane flies poorly; A tail heavy plane flies once” is the adage I’ve heard a number of times. As such, I used to fret about having too little weight in the nose, while now I find myself pushing the CG on my planes further and further back to improve the glide slope.

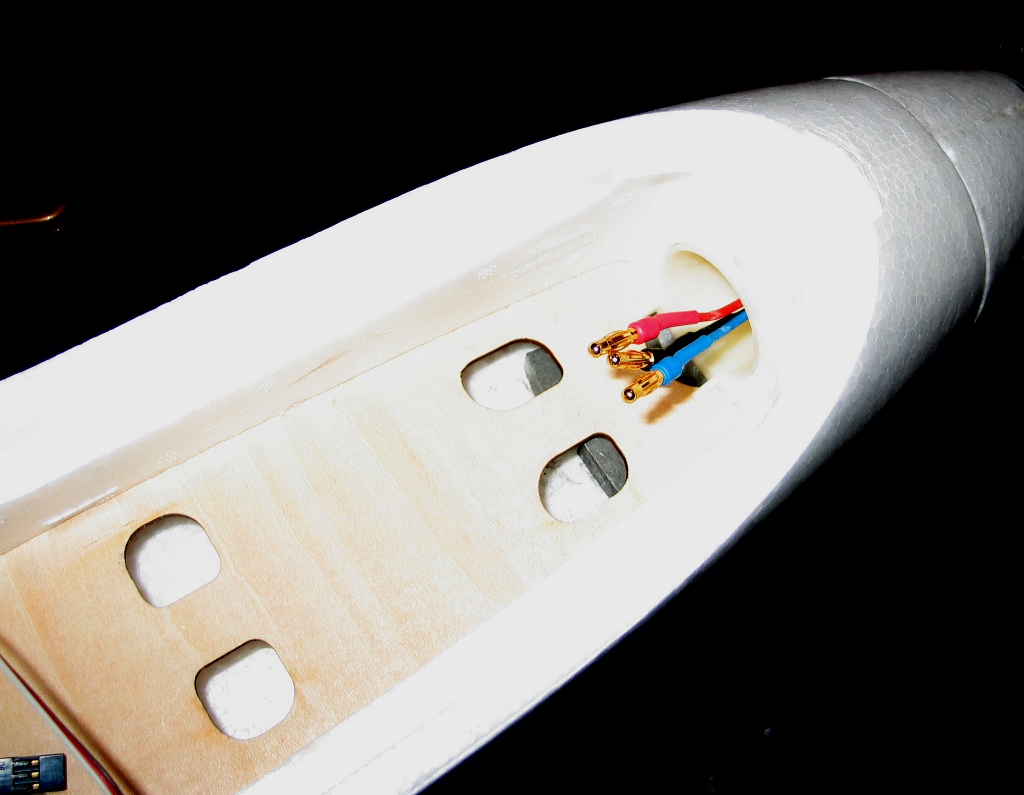

The Diamond 2500 has a pair of steel blocks glued into the nose under the plywood battery tray at the very front (visible just under the motor wires):

Unfortunately, the plywood tray can’t be removed to get at the weights, but with a flat bladed screwdriver and an assortment of picks, I was able to extract them from the rear of the cockpit area (fortunately they weren’t glued in very securely).

129 grams of dead weight! Not only is there nose weight in the Diamond 2500, but there are wingtip weights as well! Supposedly this is to reduce the roll rate, but with a big 2.5m wingspan, I can’t imagine that the roll rate is all that blazing in the first place.

The wingtip weights are glued in a little more securely than the nose weights, so I epoxied a steel rod to the weight to pull it out. After removing the weights, I glued a small block of white foam in the cavities.

Every little bit helps, as I intend to put plenty of FPV gear on this airframe. One final bit of weight reduction is the wing spar, which is a length of thick wall aluminum tubing (which slides into square steel tubes inside the wings – I’d love to remove them, but both are glued in quite securely). The aluminum spar weighs in at 133.8g, but the Goodwinds 020979 carbon fiber tube (which is a perfect fit in both length and diameter) is a mere 58.9g. All told, these weight reductions add up to nearly 9 ounces – that’s the weight of a 2500mAh 4S LiPo battery pack!

Addendum – 9OCT2015

I’m rather embarrassed to say that even though I posted this several years ago, I still have yet to actually fly the plane. However, I did just get a very helpful message from Marc Merlin, who offers some great information regarding a newer offering of the plane, a better source of the carbon fiber spar, and a full-scale pilot’s take on doing FPV flights over Burning Man! Thanks, Marc!

Howdy, First thanks for your page. I bought a BFG2600 since the diamond 2500 isn't for sale anymore, and that one comes with small steel balls in the wings, and nothing in the front, likely because the motor is a bit bigger. It does however come with a horrible heavy steel rod, but when I tried to replace it, Goodwinds 020979 doesn't work anymore as they have discontinued metric sizes. After much searching (really, this took a while), I finally found this: http://www.rockwestcomposites.com/products/t-rnd-472 and they're a perfect fit. They sell them in 2m length, but I ordered them pre-cut at 83cm, giving me 2 tubes plus a leftover for some other project. Would you mind updating your blog post to point people to that tube instead and save them the time I spent? This is my BFG2600 BTW http://marc.merlins.org/perso/rc/post_2015-08-15_BFG2600-FPV-build-with-Pixhawk-Ardupilot-3_3-_Diamond-2500-remake-from-Hobbyking_.html and this is the trouble I got into with it http://marc.merlins.org/perso/rc/post_2015-09-01_Flights-over-Burning-Man_-and-the-current-unfortunate-BMorg-and-FAA-policies.html Cheers, Marc