My big Keiyo Seiki lathe came with a simple lantern style toolpost, which is considered pretty ancient as far as toolholding technology goes. While they do have their uses (the narrow profile is quite nice for certain workpieces or setups), a quick change toolpost will be much more useful to me, especially when doing small […]

My big Keiyo Seiki lathe came with a simple lantern style toolpost, which is considered pretty ancient as far as toolholding technology goes. While they do have their uses (the narrow profile is quite nice for certain workpieces or setups), a quick change toolpost will be much more useful to me, especially when doing small scale production.

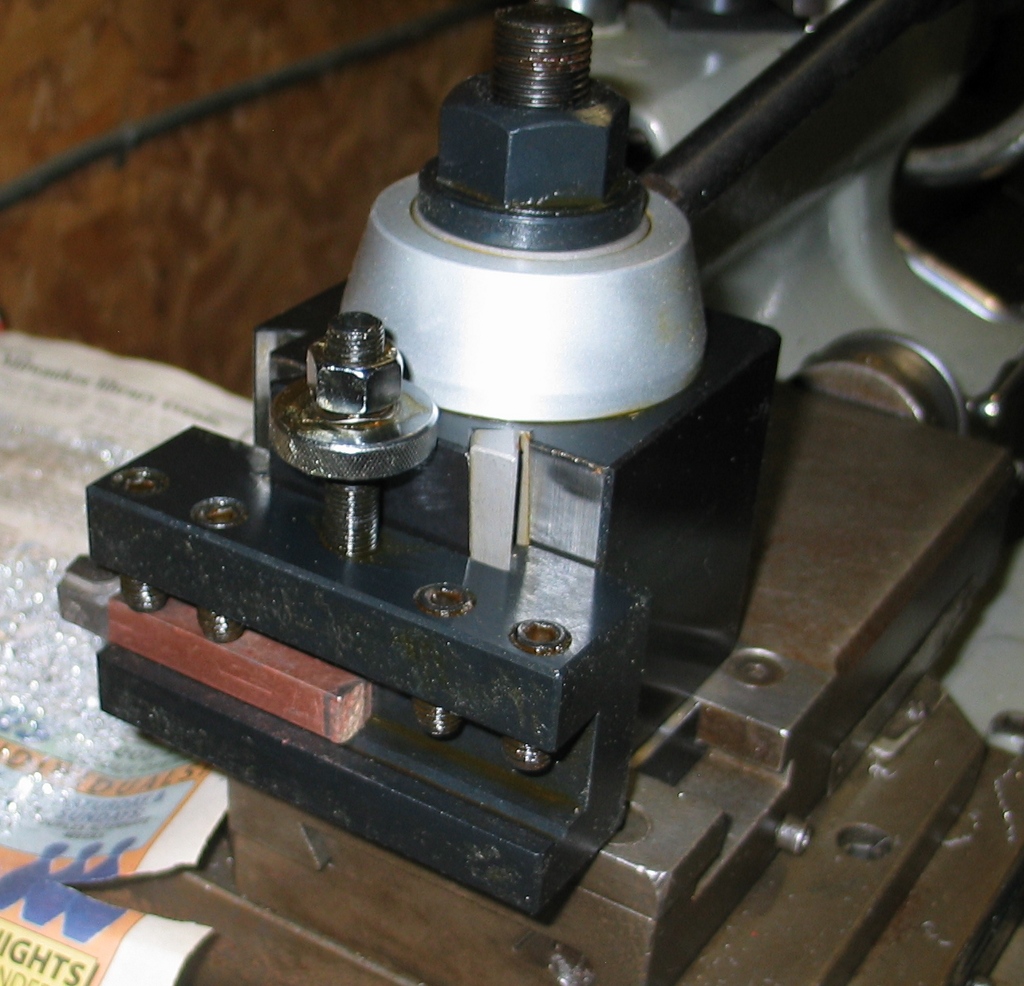

I wanted to get something really good for toolholding on this lathe, and the Aloris wedge-type quick change toolposts we had on the lathes in class were the Cadillacs of the field. Unfortunately, they have a pricetag to match – a local machinery dealer has a used Aloris CA set but wants $700 for the kit. Much as I hate to contribute to a trade imbalance, getting a Chinese made clone would be the only way to afford such a setup. I looked around at some of the offerings, and word on some of the machining forums was that the units from Quality Machine Tools weren’t half bad (but that the set screws and other hardware they come with are poor and should be replaced).

The big decision was whether to get a CXA or CA style toolpost – the difference is size. Measuring between the top of the T-slot on the lathe’s compound and the tip of a live center in the tailstock gave me a distance of 1-15/16″. Using the dimensions found in the Shars Tool Co catalog (I assumed that it’s probably the exact same stuff as what Quality Machine Tools sells), I determined that either CXA or CA would work fine for the range of sizes that their toolholders were designed for. I decided to go for the biggie and ordered the larger CA unit, as it would allow me to use 1″ square tooling. Plus, I remember chatting with a retired machinist many years ago, and he noted a rule of thumb when buying machine tools – if you have a choice between a machine that weighs 5 tons and one that weighs 7 tons, and both otherwise have identical specifications, always buy the heavier one. The extra mass means extra rigidity and better vibration dampening, which translates to being able to hold tighter tolerances and better finishes on machined parts. Never pass up the chance to listen to an old machinist – those guys are treasure chests of practical wisdom.

When the toolpost set arrived, I was rather taken aback at the weight – this was a beast.

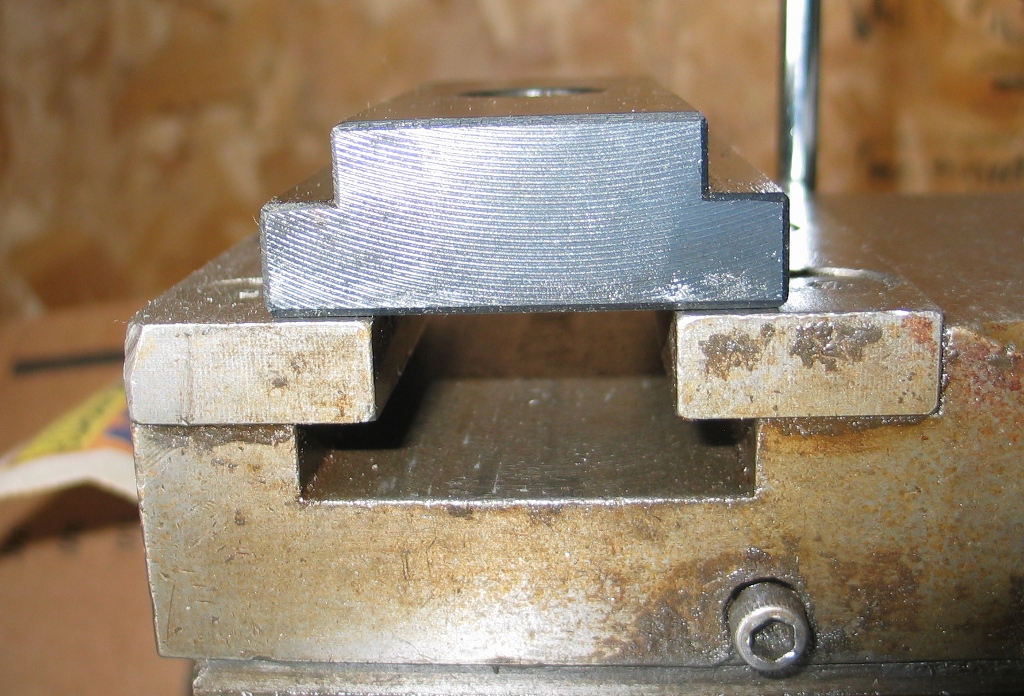

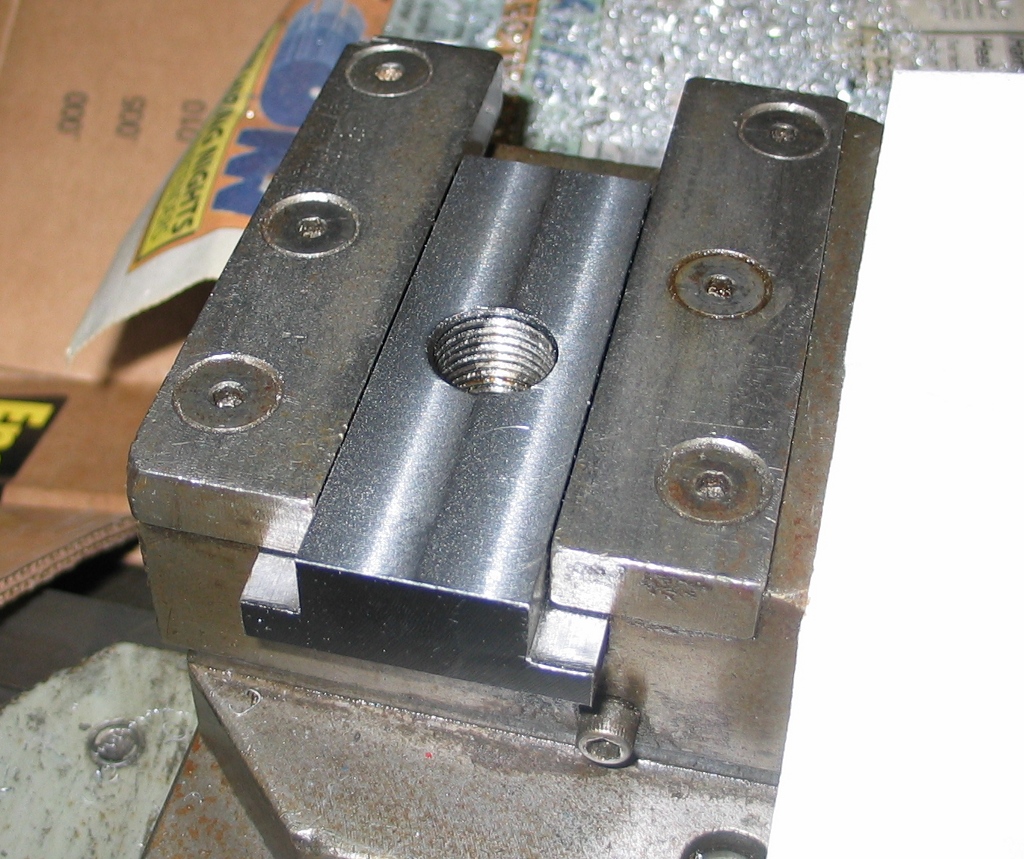

The T-nut that the toolpost bolts to the compound with is oversize so that the end user can cut it to fit (there being a very wide array of T-slot sizes). I took a few measurements and tossed the T-nut on the mill.

I still need to replace the set screws and other hardware on the toolholders, but thus far I’m quite impressed with the pieces for the price. The dovetails fit up very closely, and honestly, I can’t imagine that the extra $500+ to get a ‘real’ Aloris would actually net me much more. Now to scour Ebay for some beefy 1″ Kennametal insert holders…

We have a cnc lathe FNC1000 from your company and appears “E13 Memory Error (F00” ) in display and alarm light is lit.

The system control is Fanuc 3T-D

Would you please help me?

Ali, unfortunately I am just a hobbyist and have no connection with Keiyo Seiki (and had no idea that they ever made any CNC equipment).