I realized it has been over a year since I last wrote on the subject (though to be fair, it seems it has been about that much time since I’ve written much of anything substantial). Since I last addressed the topic in March of 2013, the apex of the “3D printed gun” story has been […]

I realized it has been over a year since I last wrote on the subject (though to be fair, it seems it has been about that much time since I’ve written much of anything substantial). Since I last addressed the topic in March of 2013, the apex of the “3D printed gun” story has been reached, and media interest in the concept has subsided. Just as promised, Defense Distributed successfully created an entirely 3D printed firearm (save for a roofing nail used as a firing pin), proved the functionality, and released the STL files.

Naturally, I downloaded the files as soon as they were released last May. Ever since Defense Distributed had stated their goal of designing, testing, and proving the possibility of a 3D printed gun, I had pondered how to actually achieve such a goal. I had my own ideas in mind, and figured I could probably design something workable in a weekend, but testing and refining the design is something else – CAD is easy, but proving the model is hard. My own line of thinking revolved around using a .410 shotshell as the intended cartridge, due to its extremely low pressure in comparison with other rounds. This would have entailed building a fairly large gun with a rather long barrel (over 18 inches so as to not run afoul of the NFA), and would have taken quite a while to print. As it turned out, DD came up with a remarkably elegant gun, far more refined than what I myself had in mind – something that stayed true to the intent of pushing the limits of 3D printing. When I say elegant, I mean elegant in the Unix sense – not something that is beautiful to behold in an artistic manner, but something that has raw simplicity and efficiency in design and operation.

DD called their creation the Liberator, an homage to the FP-45 Liberator of WWII, an equally simple, straightforward pistol that was intended to be airdropped into occupied Europe for partisans to use in resistance of German forces. The DD version is much chunkier in construction, but shares many of the same design intents – a gun that is able to fire a single shot with a centerfire metallic cartridge with as little mechanical complexity possible.

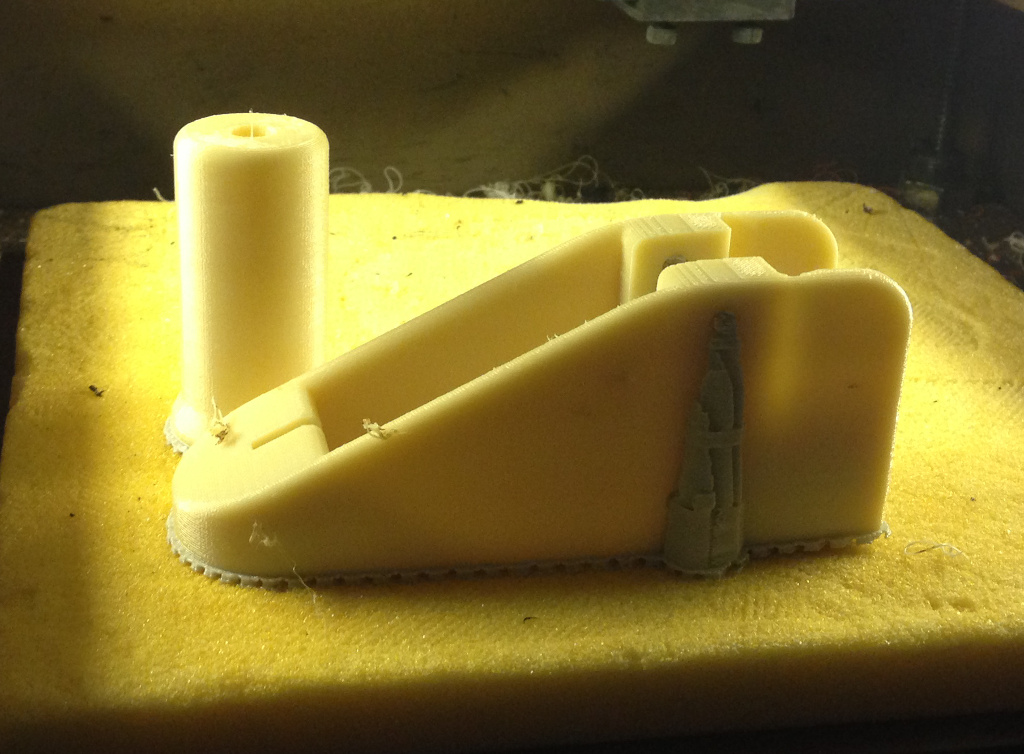

To this end, the Liberator is an impressive piece of work. It consists of only a handful of 3D printed components:

- receiver

- barrel

- breech block

- grip

- hammer

- trigger

- 2 hammer springs

- trigger spring

- firing pin

Plus a few pins that hold everything together. Of these, only the firing pin itself is metal and is actually a roofing nail – since the firing pin needs to impact the cartridge primer and deform it enough to crush the compound between the primer’s cup and anvil, material hardness is a key consideration for the firing pin (and is a material property that escapes the current capabilities of FDM printing technology).

Since I had a number of journalists ask me for my take on the Liberator, I decided to print one for myself in order to give an accurate appraisal of the design. My friend Joe (not his real name) was also interested in building and testing one to make a proper evaluation, so we collaborated on doing a proper test shortly after the design was released.

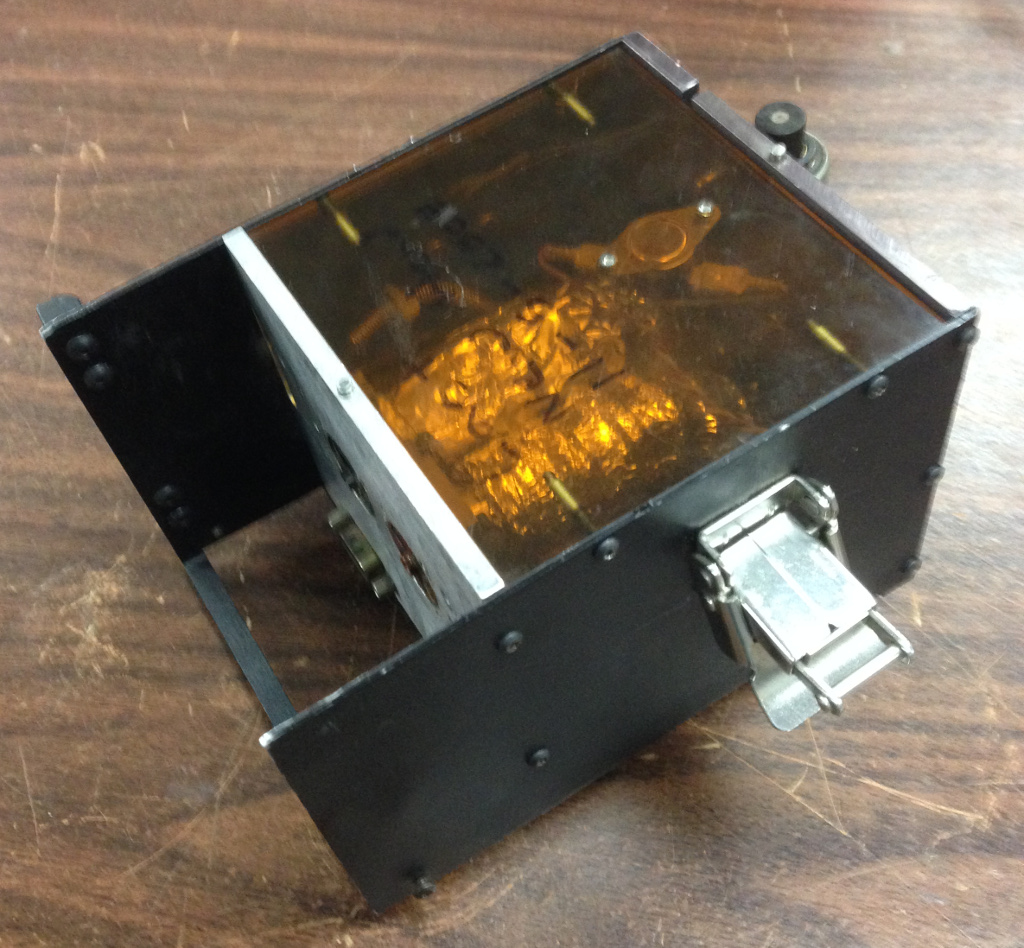

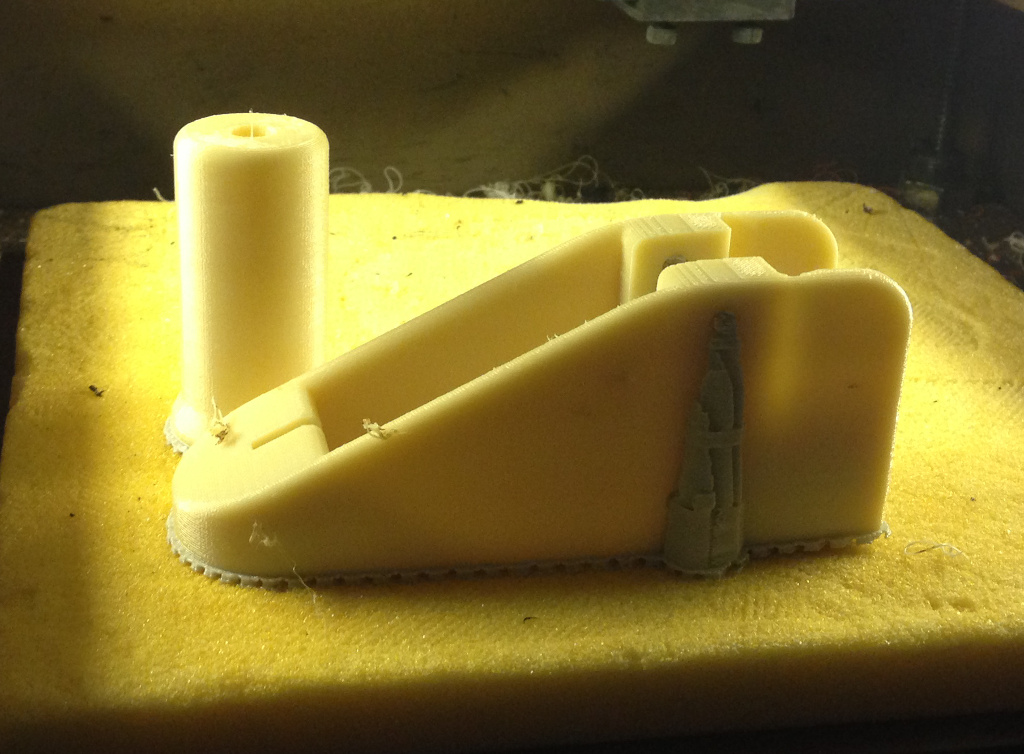

I opted to use up the rest of my MG47 filament for the various Liberator parts. Unfortunately, I lost extrusion halfway through printing the receiver:

Rather than re-print the entire thing (which was over 30 hours), I decided to place the part in the mill vise and plane off the top, then glue on a replacement top half.

I took the opportunity to also glue in a metal block for compliance with the Undetectable Firearms Act. I bought some 1″ square steel bar and sawed a piece off the end, then found a little bit of scrap to fill in the sides. All told, I had 147 grams of steel, which should be more than sufficient to satisfy 922(p) (the specific section of US law codifying the UFA).

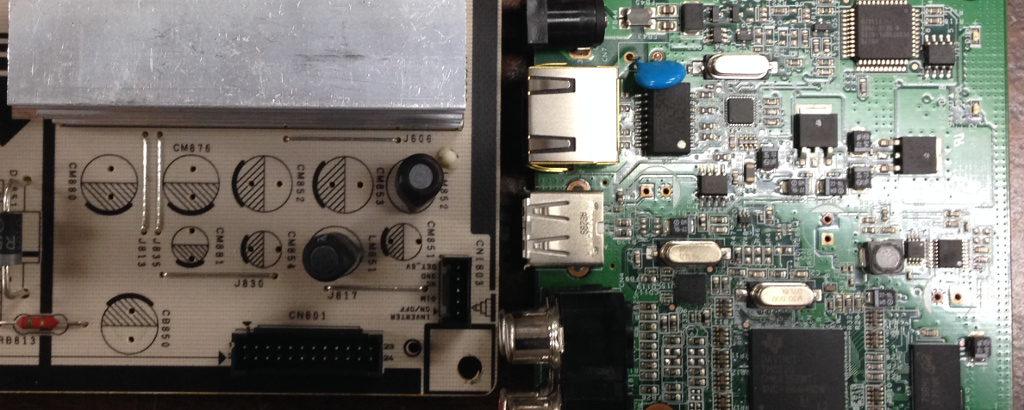

Insight is a powerful piece of 3D printing software, and I was able to go back to my sliced version of the receiver and delete all the layers from the file that I had already successfully printed. This allowed me to print just the upper half of the receiver, and I printed a barrel at the same time for good measure.

Note that the .STL file for the Liberator barrel that was originally released is a smoothbore with no rifling (just like the original WWII FP-45 Liberator). This theoretically makes it an AOW (Any Other Weapon) under the 1934 National Firearms Act (NFA). The definition of an AOW is rather convoluted (and somewhat contested, given U.S. v. Davis), but it is intended as a catch-all category for firearms not otherwise defined by other categories (hence, ‘Any Other’). A pistol or revolver with a smooth bore is generally considered an AOW, and for an unlicensed individual to make one, they need to submit a Form 1 to the ATF along with fingerprint cards, a passport photo, $200, and a sign-off from their chief law enforcement officer. In other words, if you want to try printing a Liberator and don’t want a lot of hassle, make sure the barrel has rifling in it to avoid trouble. Even modern reproductions of the FP-45 Liberator have tiny (and ineffective) rifling grooves in order to remain compliant.

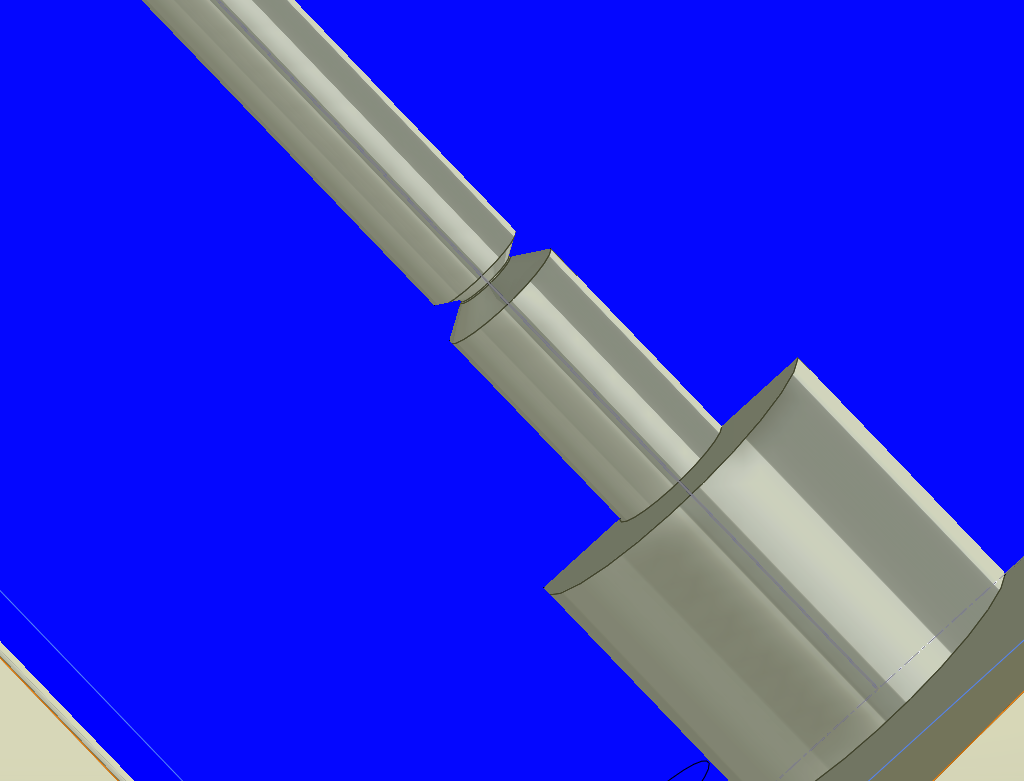

I made sure to add rifling to the print itself, as rifling it afterwards would necessitate equipment that I simply don’t have (but would love to build someday).

Although the top half of the receiver printed without loss of extrusion, there was still a significant amount of warp on the bottom. I opted to mix up a batch of epoxy with microballoons and colloidal silica (a thickener) to glue the two halves together.

I didn’t actually print the needed pins and just used some spare sections of metal tubing instead.

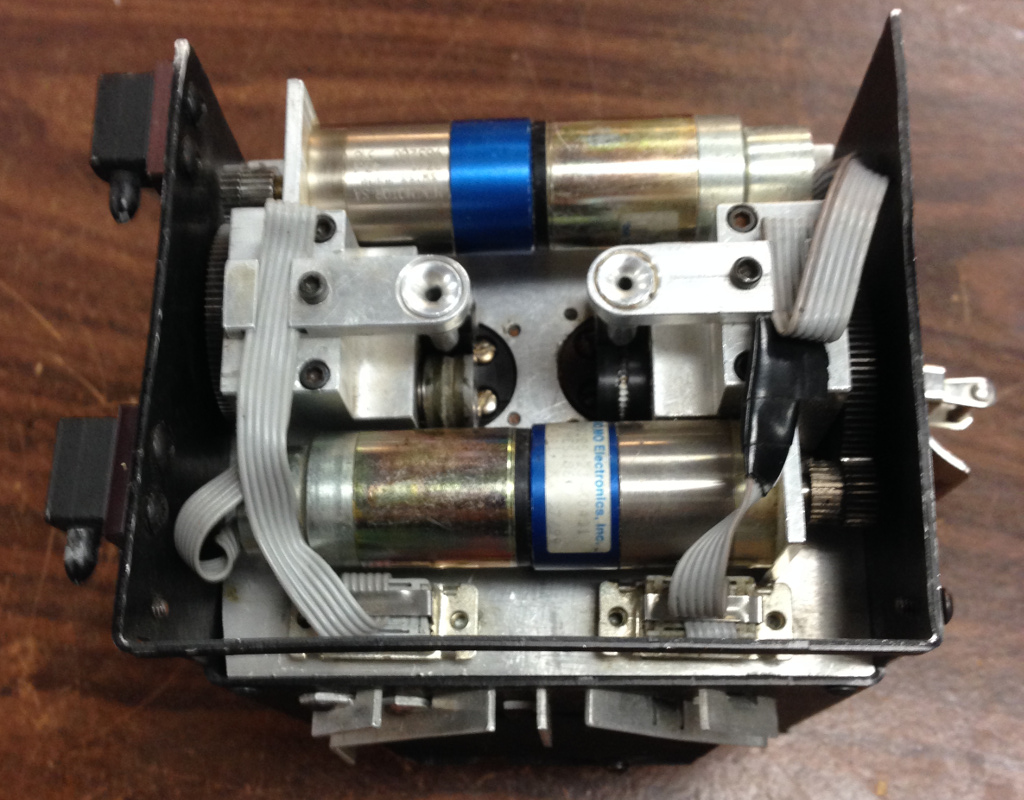

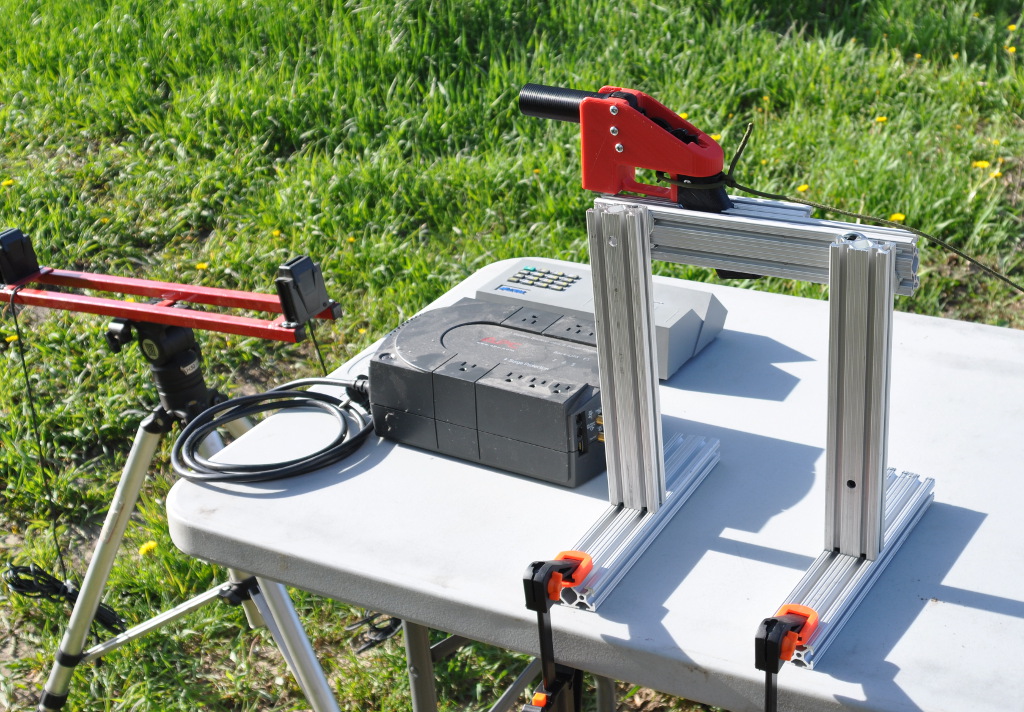

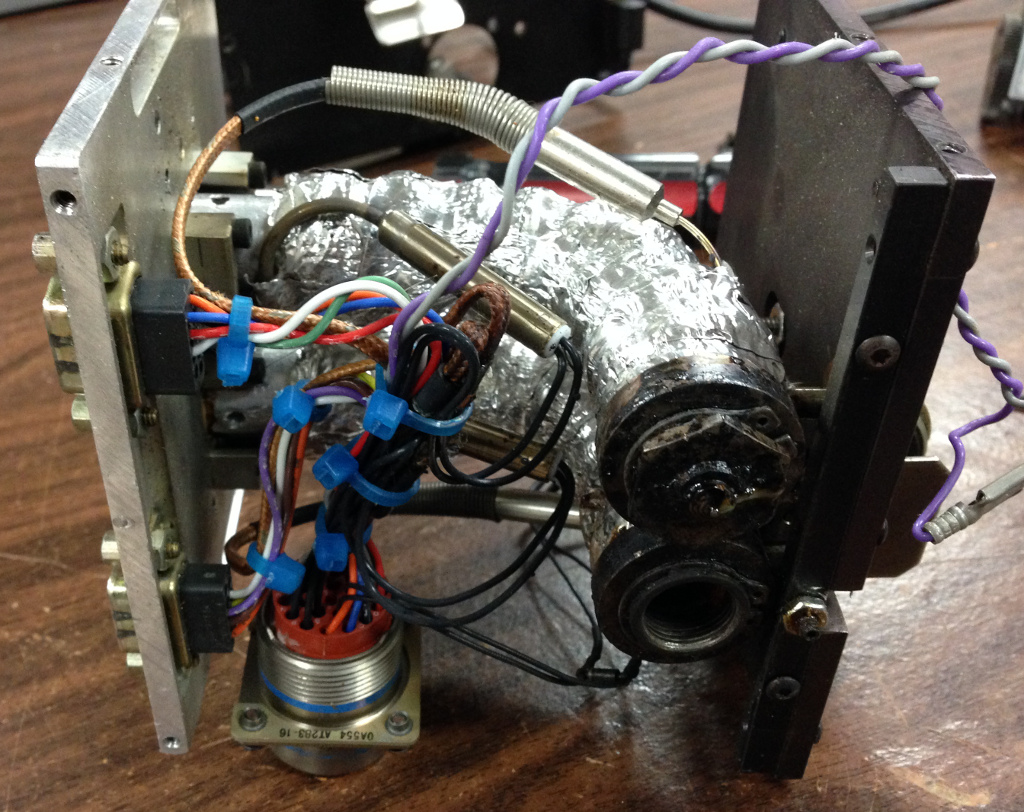

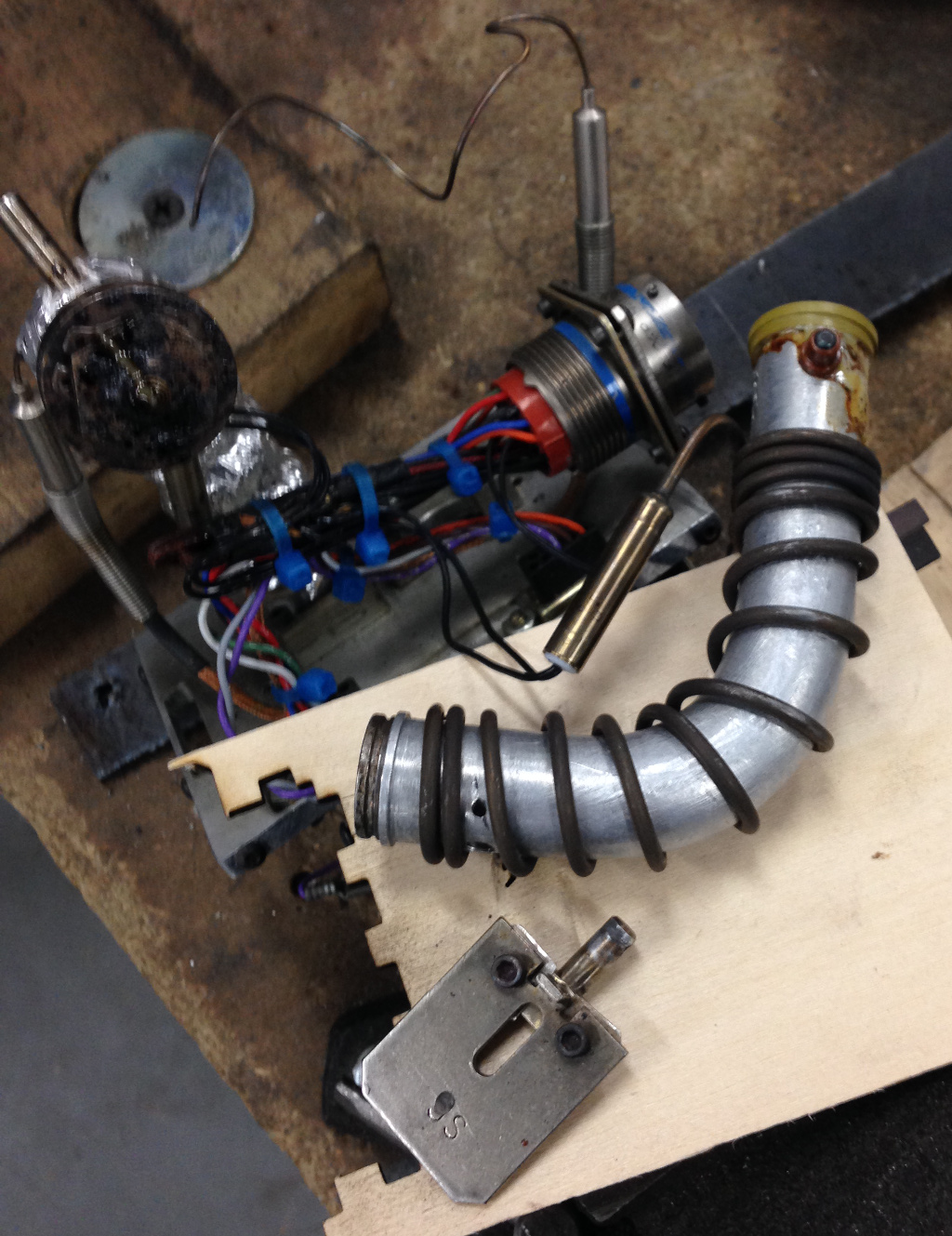

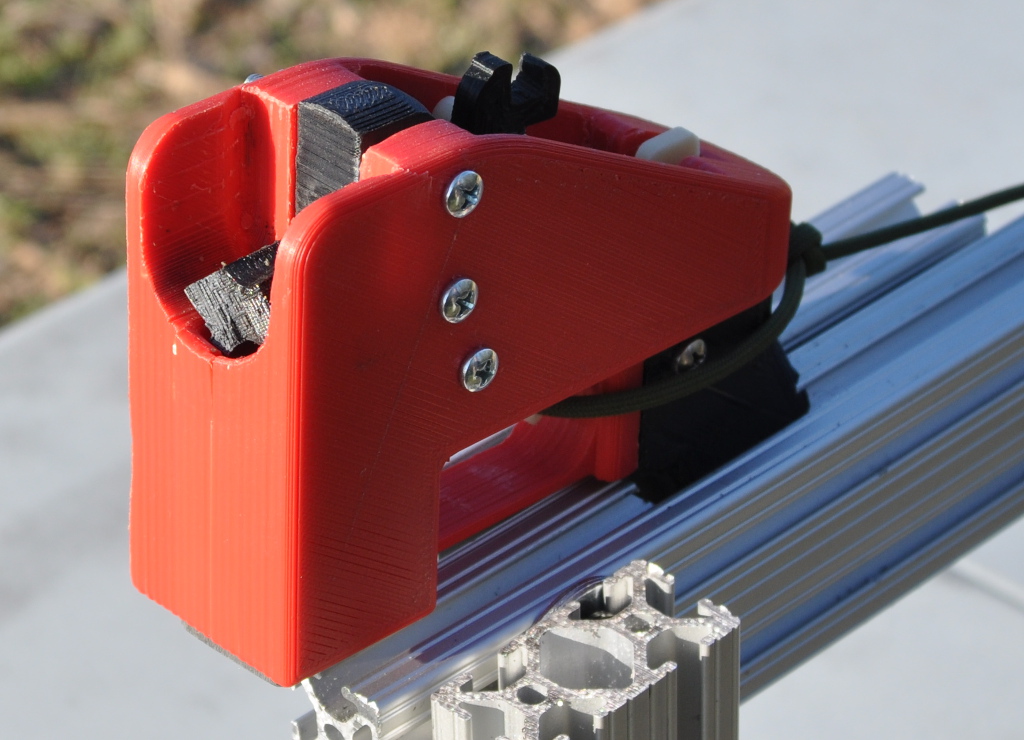

Meanwhile, Joe used his Lulzbot to create a remarkably robust receiver out of standard PA-747 filament. He had tweaked his machine to provide extraordinarily dense prints with virtually no porosity. We decided to test out his version to determine just how well the design works, its durability, and to get some velocity data to determine actual muzzle velocity. Additionally, news stories on the Liberator seemed to generally claim that a $10,000 (or more) 3D printer was required to print the Liberator. We wanted to dismiss this notion and show that even a $1000 printer is perfectly capable of printing high strength objects.

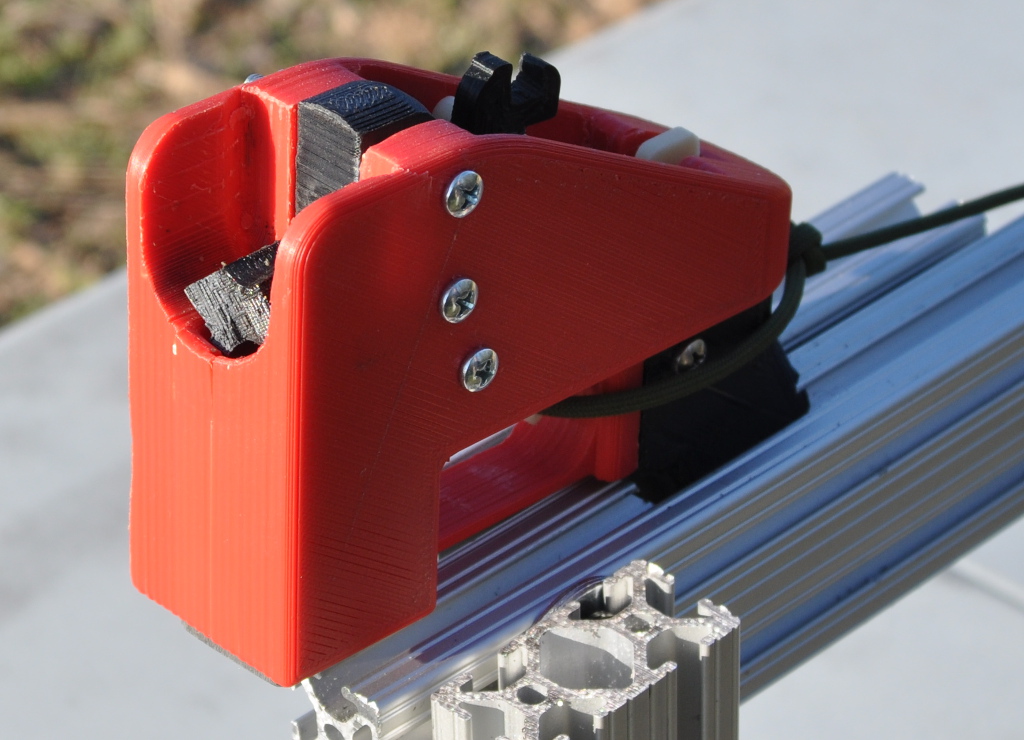

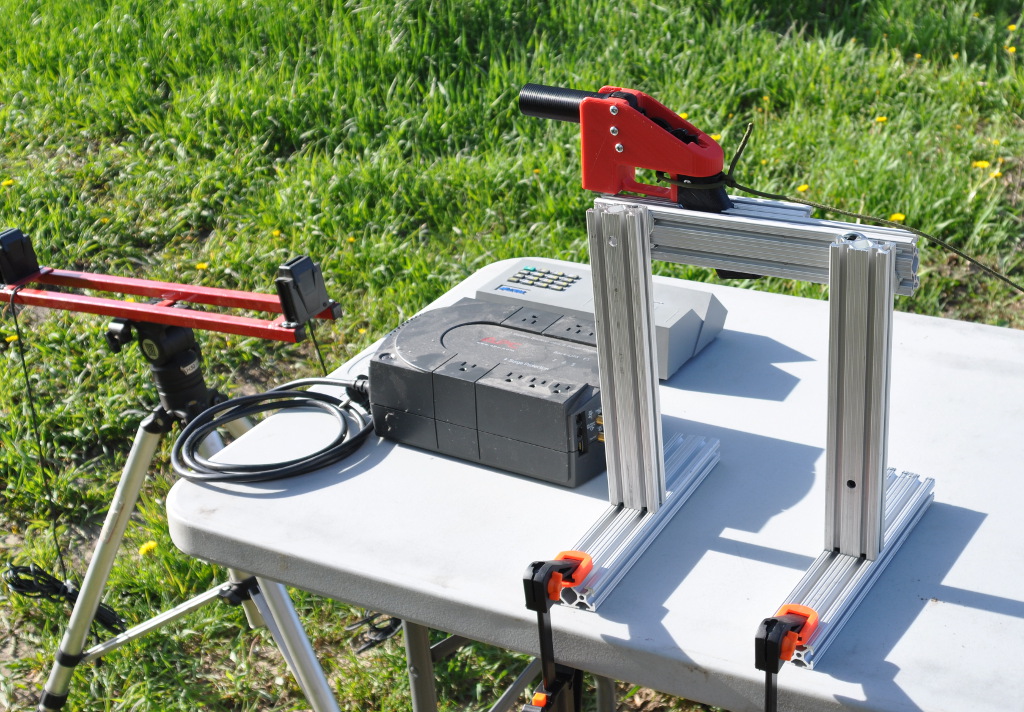

In mid-May of last year, we met up to actually perform the testing. Our test rig consisted of an 80/20 frame to actually mount the Liberator to, which itself we clamped to a folding table. In front of the test rig, we set up the sensors for my PACT chronograph (used to measure the speed of the fired bullet). For safety, we used a 30 foot length of paracord to pull the trigger. Note also that we used machine screws to actually mount the breech block within the receiver, rather than 3D printed pins. Additionally, Joe’s barrel was slightly longer than the published Liberator barrel.

We had a great deal of difficulty getting the gun to fire in the first place, making nearly ten attempts to get it to go ‘bang’. The first issue was getting the sear tail to actually release the hammer, so we replaced the trigger bar with one printed on my machine. After this, the primer was indeed getting struck, but it did not seem to be igniting – we replaced the springs with ones from my machine as well. We would wait 30 seconds after each attempt in case there was a hangfire (thankfully we never had one during the testing). We wondered if headspacing could be an issue, so we pulled Joe’s barrel and put in one that I had printed on my machine. We also replaced the .380 cartridge we had been using with a fresh one in case it was a dud.

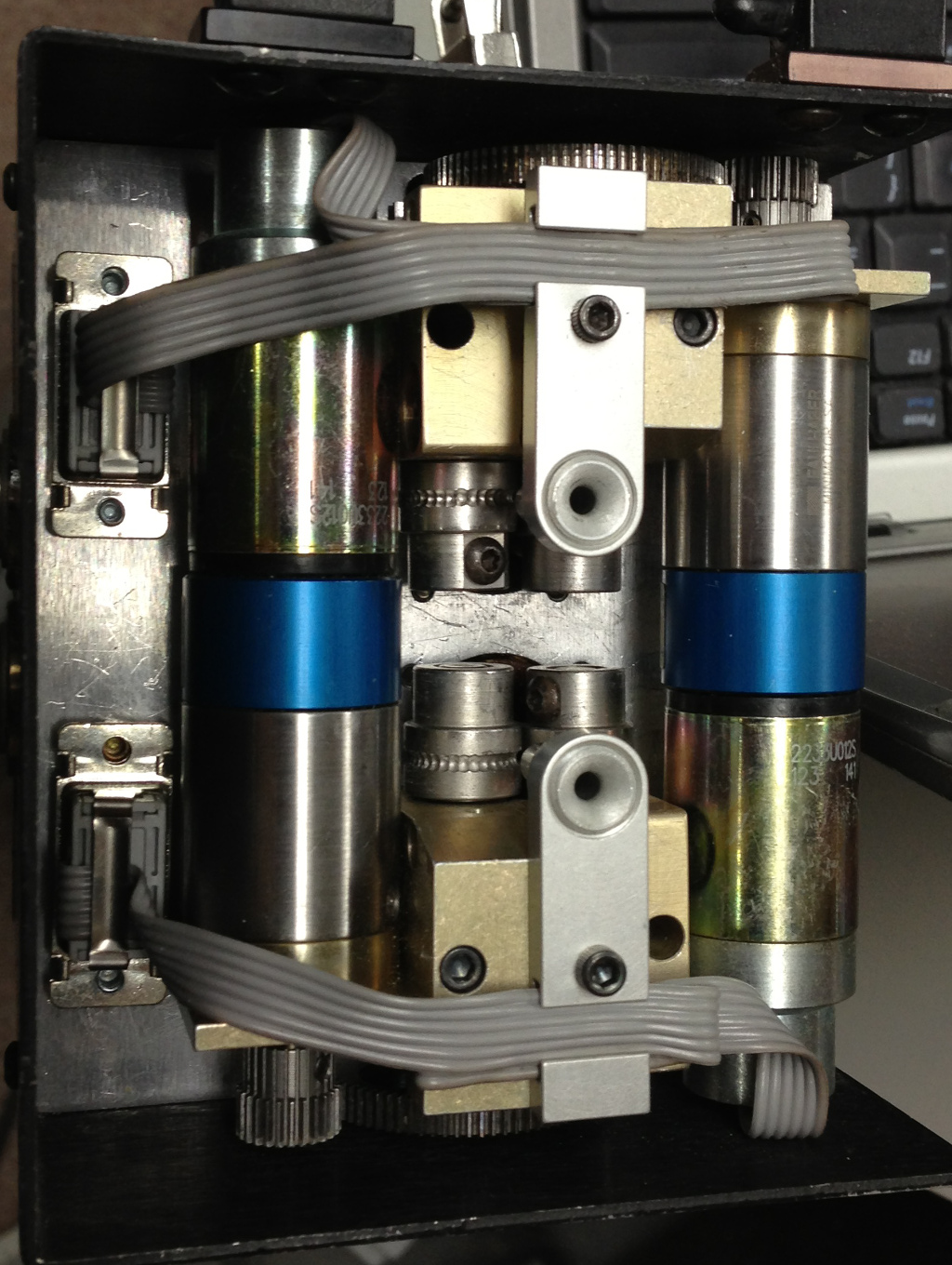

Our next attempt did indeed go ‘bang’, and there was very little of the barrel left in the receiver. My Stratasys FDM 1600 still has a bit of porosity in its output, and I hadn’t done a solvent vapor treatment on the barrel as was recommended by Defense Distributed. Also, the round was a very tight fit and had to be pressed into the barrel – it’s possible that the bullet became dislodged, seating further down within the case and causing higher pressures when fired. While the barrel was destroyed, we finally achieved primer ignition, so we put Joe’s barrel back in and continued testing.

With things finally working (if not smoothly), we proceeded to fire off as many shots as we could manage during the available sunlight. Here’s a short video of the successful shots made: Lulz Liberator testing video

The video hints at some of the issues we ran into during testing. We didn’t have the retainer for the firing pin installed, so the firing pin would rocket out the back during every shot. We used a piece of masking tape on one attempt (you can see it fly up after the shot) to try and keep the firing pin in place, but the hole punched through the tape shows that this did not work at all. We only had one roofing nail, but fortunately Joe happened to have along extra machine screws that he used for assembly and was able to fashion a replacement firing pin each time by cutting and filing it with a pocket multitool. We had to make the firing pin longer each time as well, since each subsequent shot increased the headspace, with the cartridge becoming seated further and further down the barrel each time.

The 3 screws holding the breech block in place also became noticeably bent as testing continued, so we replaced them halfway through.

Here’s what the Lulzbot printed barrel looked like after its first successful firing. The cartridge has actually been pushed back a bit (hence pushing back on the breech block and bending the retaining screws as noted). You can also see white spots forming (known as crazing) as a result of the internal stress. Finally, the primer has been pierced, allowing gas to erupt out the back of the cartridge, which is an undesirable behavior. However, this is not a fault of the Liberator’s design, but a side effect of using a roofing nail or ‘field expedient’ machine screw – the sharp nose of the nail or screw actually punctures the primer cup, whereas proper firearm firing pins actually have a carefully rounded nose so that they dent but do not pierce the primer. In fairness, however, pierced primers are not a great concern on a disposable firearm such as the Liberator or its WWII ancestor. Continually piercing primers will allow the hot gases to erode the bolt face, firing pin hole, firing pin tip, etc. in a conventional firearm, but for a disposable gun designed to operate only a few times, this is admittedly a minor design quibble.

One thing the photo does not really indicate is how firmly the brass case is actually stuck inside the barrel. In a conventional metal barrel, the brass does expand somewhat during firing, which is actually beneficial in sealing the case to the chamber walls in a process known as obturation. The brass relaxes slightly as the bullet exits the barrel (which allows the internal pressure to drop back down to atmospheric levels), but since ABS plastic is much lower in strength than steel, the brass case expands greatly in the Liberator making conventional extraction all but impossible. In our case, we needed to use a hex wrench and a rock to beat the expended cartridge out of the barrel.

Unsurprisingly, the walls had expanded so far that the case had actually split.

More surprising to us, though, was the fact that the barrel bore looked entirely unscathed (not only by the projectile, but by the hot propellant gases). The photo really doesn’t show it, but in looking down the bore, the finish appeared just the same as in the unfired state. Both Joe and I presume that there is so much bore expansion during firing that the bullet itself isn’t even touching the rifling. Granted, the rifling would have done almost nothing anyhow (a copper jacket is still much harder than ABS plastic).

We only managed to record two shots with the chronograph (we weren’t using skyscreens, and they probably would have helped). The captured velocities were 498.2 and 465.1 fps, for an average of 481.7 feet per second (146.6 m/s). By comparison, the very same round fired out of a conventional .380 pistol will be well over 900 fps. Consider that kinetic energy (or ‘muzzle energy’ in firearms parlance) increases as the square of velocity, and the difference is quite dramatic – the Liberator only achieves a muzzle energy of 49 foot-pounds, or roughly a quarter that of what a standard .380 pistol provides. By way of comparison, a major league fastball delivers twice as much energy, and one person has actually died as a result of being struck with such a pitch (yet a year later, despite proclamations of mayhem and anarchy in the press, there have been zero deaths or even injuries from 3D printed guns). In the end, then, the Liberator is not at all a weapon of physicality, but a weapon of philosophy, able to challenge preconceived notions regarding governmental control over the sharing of information. Which, whether you agree or disagree with his views and actions, is precisely what Cody Wilson set out to accomplish in the first place.

Somewhat unsurprisingly, only a few days after DD posted the .STL files for the Liberator on their site, the US State Department sent a letter to Cody, demanding takedown of the Liberator files and 9 other designs that had been posted on Defense Distributed. The authority for this stems from ITAR, the International Traffic in Arms Regulations, which controls import and export of defense related articles, including information related to such items. That acronym may ring familiar to old hands of the internet, as it is the very same statute under which the US government blocked export of Phil Zimmermann’s PGP encryption software in the mid-90s, which saw Phil under criminal investigation for “munitions export without a license”. While the case against Phil was eventually dropped (and Cody/DD have not been actually charged with any wrongdoing), the parallels are striking. Like Phil’s case, it will undoubtedly be many years before the issue is resolved.

What struck me oddly about the State Dept. letter were the 9 other designs listed as takedown targets. In my opinion, these were picked entirely at random in a perfectly transparent attempt to hide the fact that the Liberator files were in fact the sole items of interest. Specifically, item 6, “Sound Moderator – slip on” was actually designed by noted RepRap contributor (and airgun enthusiast) Vik Olliver and is still available on Thingiverse. If this was truly an ITAR violation, then why did the State Department not do anything when Vik originally ‘exported’ the file from New Zealand to Thingiverse servers in the US, and why has Thingiverse/Makerbot/Stratasys not received their own ITAR takedown letter for continuing to host this design? I could opine a great deal more on the topic, but since I attempt to limit my blog writing to technical matters, I’ll curtail my musings.

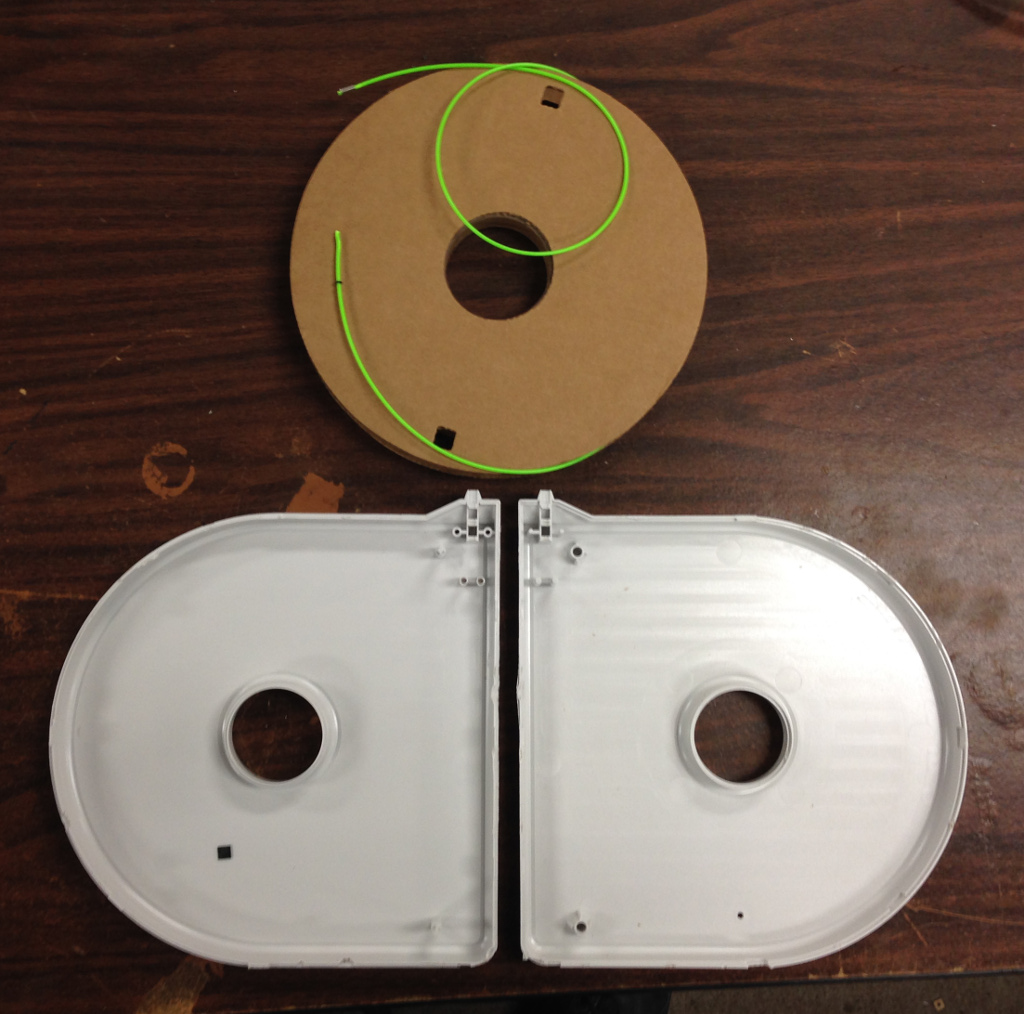

Other interested people have printed their own versions of the Liberator as well – mashable.com has a superb 8 minute documentary called “I Printed a 3D Gun“, which I highly recommend watching. Travis Lerol (who has also experimented with printing AR lowers on his 3DS Cube) attempts to give his own Liberator a try, but it fails to ignite (spoiler alert). Travis tells me that he has since managed to get a round to fire, though it took about 200 attempts. A number of design remixes of the Liberator concept have also been posted online, though very few (if any) have actually been printed and tested.

I was very honored to be asked by Professor Hod Lipson to make a presentation at the Chicago Inside 3D Printing conference on the topic of 3D printed firearms on July 11. I was scared stiff to do any sort of public speaking, but thankfully there weren’t many people in the audience, and I had a few friends in attendance for moral support. I’m very glad I attended, as I was able to chat with so many notable people in the field – not only Hod Lipson, but Avi Reichental (of 3D Systems), Scott Crump (of Stratasys), Scott McGowan (of Solid Concepts) and especially Ralph Resnick (of NAMII) – thanks to you all for your time and attention. Chatting with Scott McGowan and some of the other folks from Solid Concepts was especially interesting, given that only a few months later, Solid Concepts would release their own 3D printed gun, the 1911 DMLS. As a fan of John Browning‘s entire portfolio of work (and especially the M1911 pistol), I was thrilled to see such an iconic, century-old design recreated with cutting-edge technology. Solid Concepts is now actually selling the 1911 DMLS in a limited run of 100. While I wish I could afford one as a collectible (Scott, if you have an extra, please drop me a line!), I’m simply happy to see the whole 3D printed gun media story finally reach its logical conclusion: 3D printing is simply another manufacturing technology, and its application to firearms is no different than the development of milling machines, investment casting, CNC, polymers, and on and on.

Addendum: I had initially wanted to cover much more of the work done in the past year by others exploring the intersection of gunsmithing and 3D printing, but this post took long enough to write as it was. Fortunately, Andy Greenberg (who interviewed Joe and me for several stories last year, and is a superb technology reporter) has an excellent rundown of the various designs being experimented with by FOSSCAD.