A few weeks ago, a sharp-eyed coworker mentioned that he saw a rapid prototyper on Craigslist that I might be interested in. It turned out to be a Zcorp Z402C powder bed machine (a technology developed at MIT, which lays down complete powder layers and fuses them selectively rather than depositing material in a specific […]

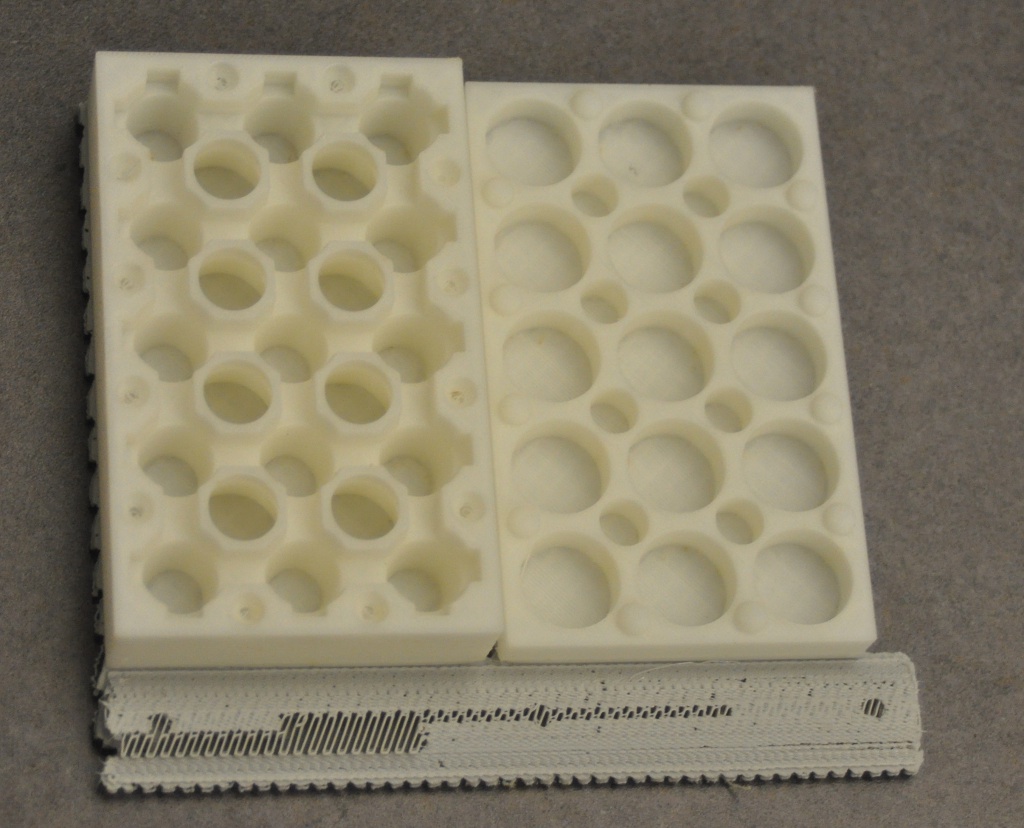

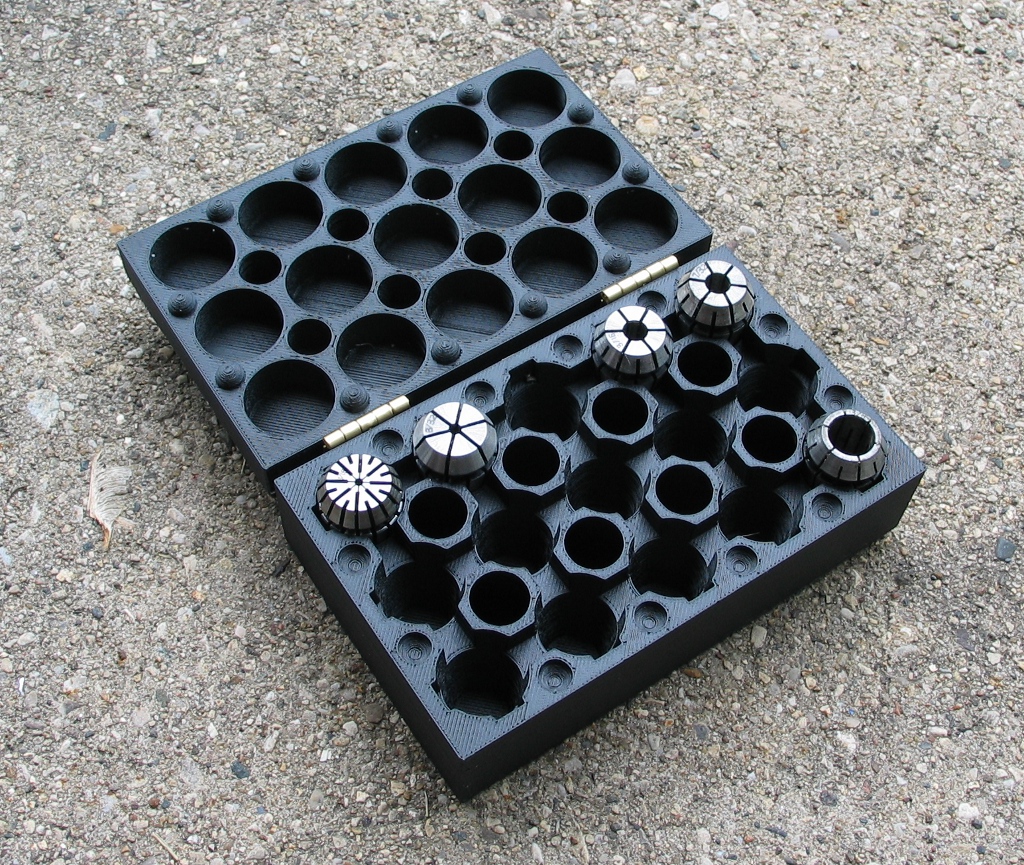

A few weeks ago, a sharp-eyed coworker mentioned that he saw a rapid prototyper on Craigslist that I might be interested in. It turned out to be a Zcorp Z402C powder bed machine (a technology developed at MIT, which lays down complete powder layers and fuses them selectively rather than depositing material in a specific path like my Stratasys). The machine came with a depowdering station and a wax infusion machine, which are nice bonuses – not all used Zcorp machines come with them. The machine was residing at a high school (which was blessed with a very nice technology program) and was currently inoperable (though had been mechanically sound when put into storage some 3 years ago).

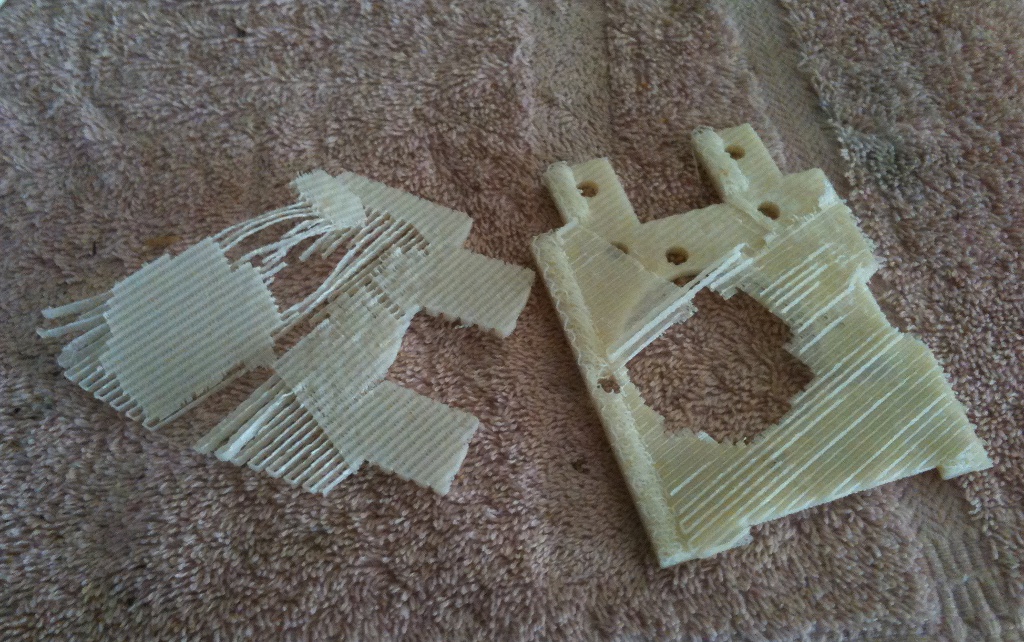

The seller said that they had diagnosed the problem to be a faulty motherboard (thankfully meaning a standard PC mobo, and not a custom proprietary PCB), and later, upon reviewing the photos I had taken when inspecting it, the issue jumped out at me:

Ho, ho! All that ails the motherboard are some blown capacitors. Getting this thing running seemed like a distinct possibility. Just one problem – I really didn’t need (or have space for) another rapid prototyper, much less a powder bed unit. But for a measly $500 for the whole system, I couldn’t just let it go. Fortunately, I managed to convince Frankie (not that it took much arm-twisting) that it would be a perfect addition to the technology lab that he’s setting up for the art school. Plus, much like with the Cole drill, I like knowing where I can put my hands on a particular tool, even if I have no use for it at the moment. So I told the seller to consider it purchased, and I’d be by in a week to take delivery.

After replacing the trailer hitch on the truck as well as the long-missing passenger side rear view mirror, I had a vehicle that met U-Haul’s rigorous requirements for trailer rental (in retrospect, I could have pulled up on a moped with a ball hitch and they still would have gladly taken my credit card). Loading the equipment onto the trailer was easy – being in a high school’s shop, there were plenty of kids to heave the stuff onto the trailer and strap it down. Once at Frankie’s studio that evening, we had notably less manpower at our disposal, but Frankie and I managed to manhandle all 3 pieces into the lab with no casualties. Charles dropped by later, and we all surveyed the bounty of the haul. We found the original machine invoices, and I forget what it all cost, but it was well over $50,000 when new. There were a few bottles of binder, a box of powder, documentation, little odds and ends… But we still had a dead machine. I took the motherboard and hard drive home to source replacement caps and image the hard drive (I recall reading somewhere that it’s a good idea to have a backup image of your Zcorp’s drive). Meanwhile, Frankie found the exact motherboard on Ebay as a refurbished unit, and bought it right away for about $175. Expensive, but when dealing with decade old PC equipment, it can be hard to find specific items. At any rate, we can always replace the caps on the original in the future if the refurb unit blows up someday.

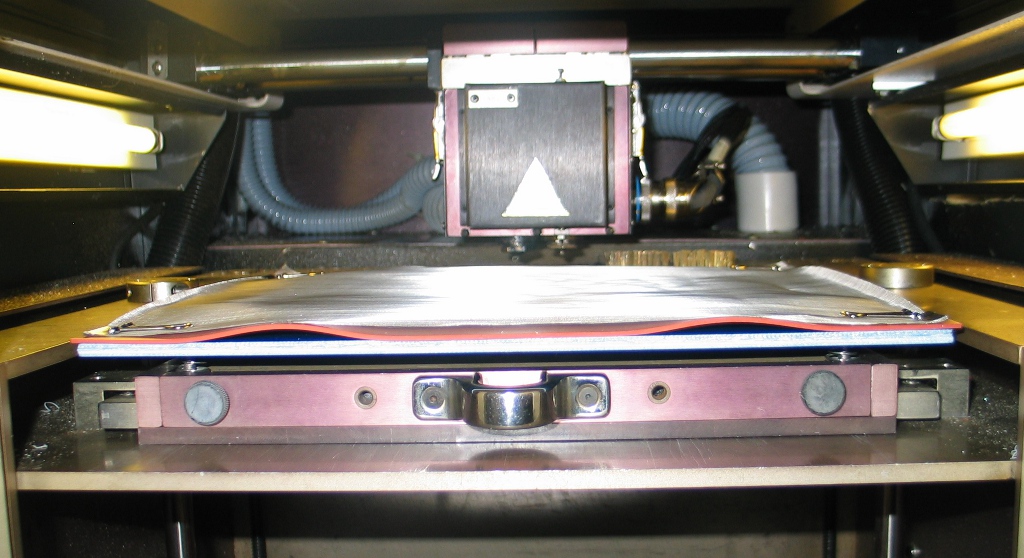

The other week, we all met again at the studio to install the replacement motherboard and flip the power switch for the first time. I had wisely snapped a few photos of the cable connections before taking out the busted motherboard, so installing the new one and putting the drive back in place went quickly. Powering on the machine didn’t work, though – after about 20 minutes I found that I had plugged a ribbon cable in 2 pins off – after fixing this, the power button actually functioned (interestingly, the power button connects right to the pins on the PC motherboard, which remains in full control – I would have expected some other power/monitoring board to control the system at such a base level).

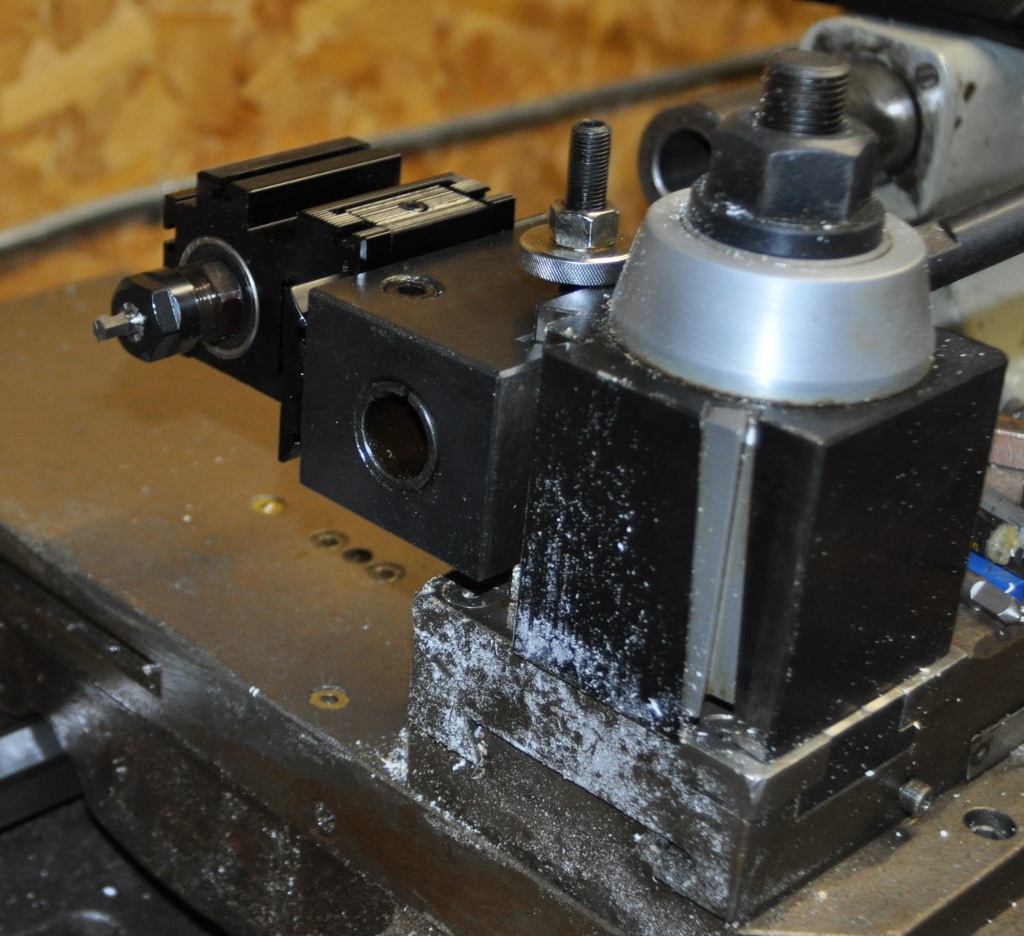

After that, we had a machine that was powered on, but not actually doing anything. We poked at it for a good long while, trying to coax it into doing the startup dance that the manual indicated it should be running (the video output that we hooked up really wasn’t of much help for anyone who wasn’t a trained Zcorp technician, but it did seem to indicate that the machine was at least reading some encoder feedback). After much web searching, Frankie tried jumpering some photosensors to bypass them, and suddenly the machine began to move the gantry of its own accord. Victory!

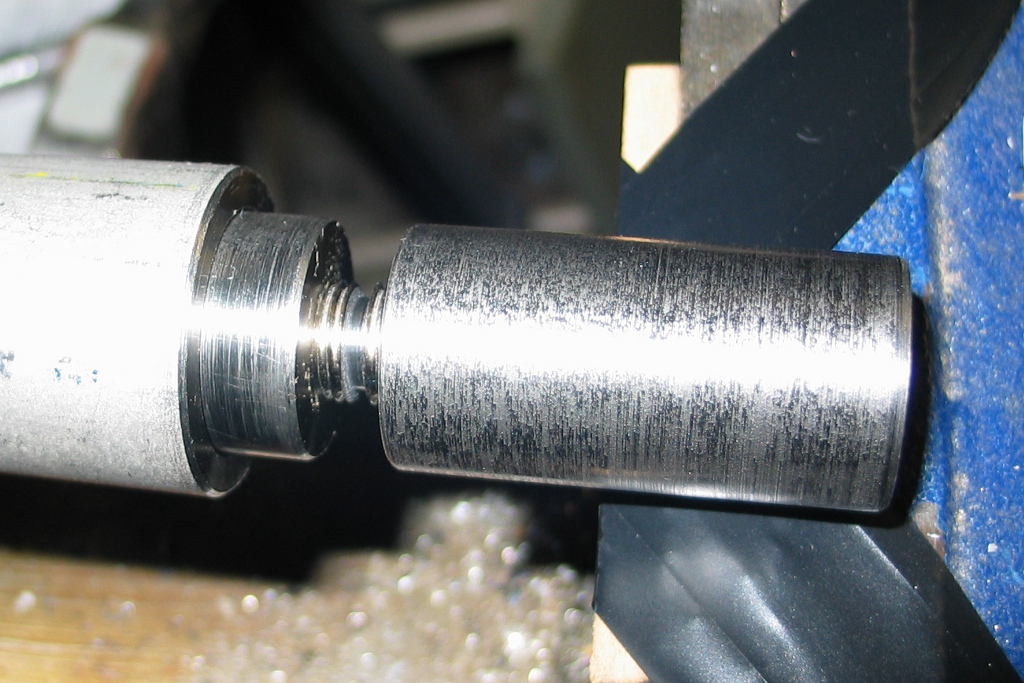

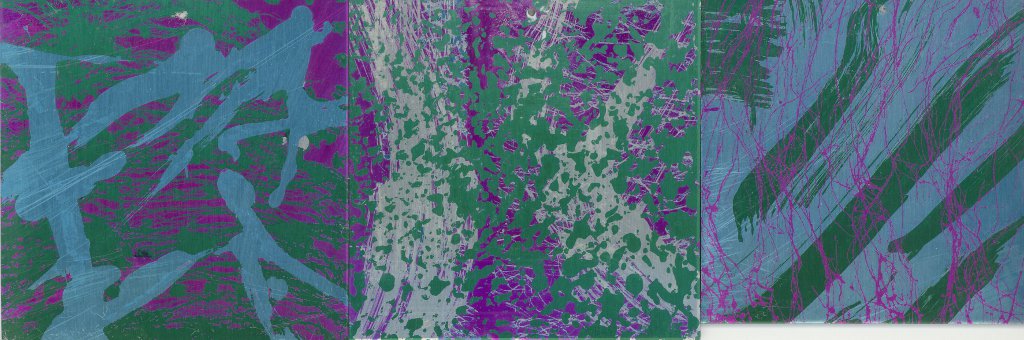

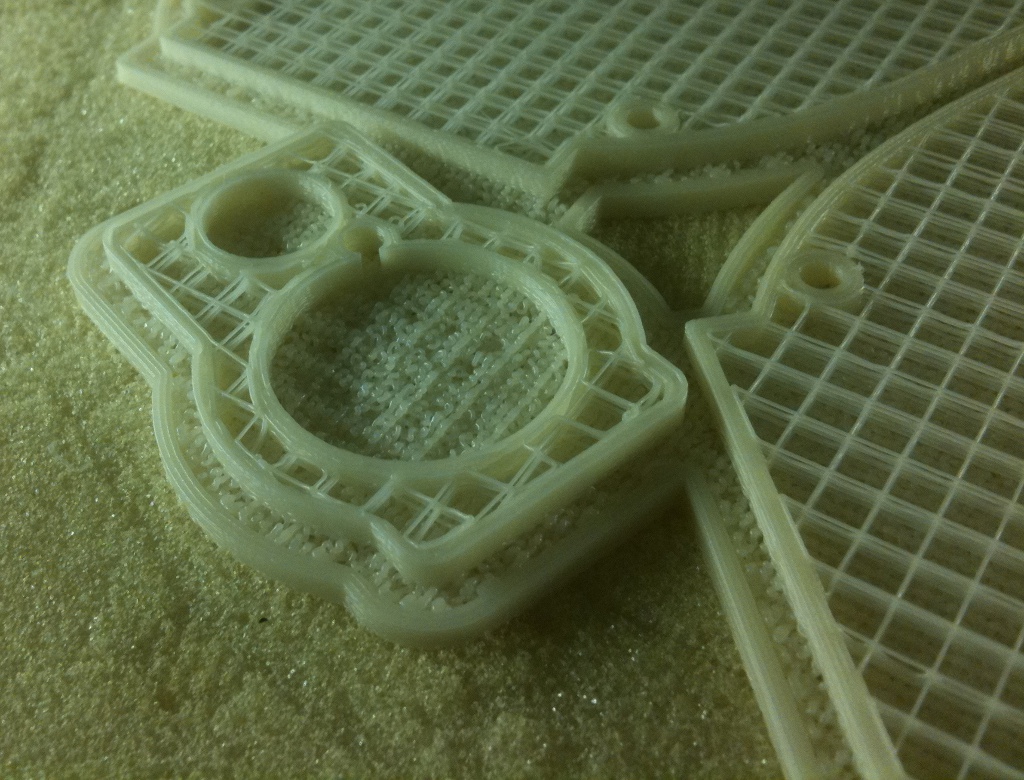

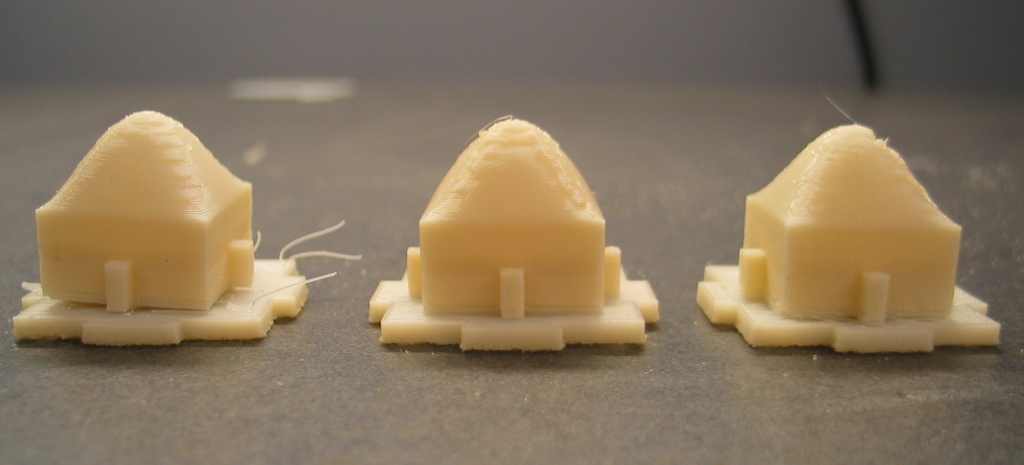

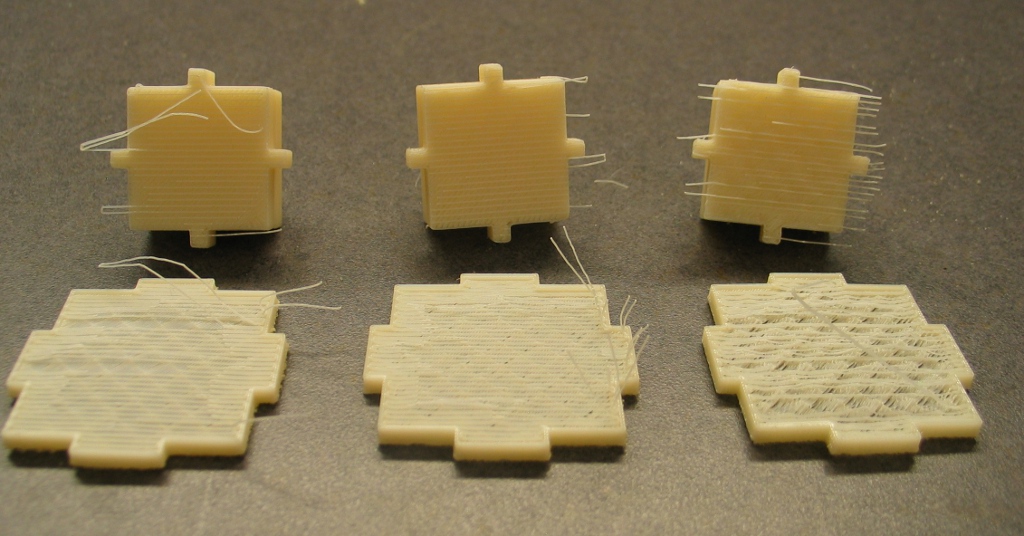

We still didn’t have a null modem serial cable to communicate to the Zcorp with (needed to actually download files to it for printing), so we called it a night, pleased that we had resurrected the beast. This past weekend, Frankie managed to scrounge up the needed cable and set the machine running a few layers. It still needs calibration, the water cleaning the binder lines needs to be flushed through, and the screws and shafts could use a bit of cleaning and lubrication, but it’s a very healthy start to what I hope will be a great machine for the lab.